How Flexible is Tungsten Wire?

In the realm of materials science, tungsten wire stands out as a symbol of strength and resilience. However, the burning question on many minds is, "How flexible is tungsten wire?" The answer might surprise you. Contrary to the common perception of tungsten as a rigid substance, recent advancements in technology have led to the creation of tungsten wire with impressive flexibility. This article will delve into the properties of tungsten, the manufacturing processes that contribute to its flexibility, and its real-life applications across various industries.

Properties of Tungsten

Tungsten, known for its remarkable properties, boasts a high melting point and exceptional strength. Traditionally associated with rigidity, tungsten has been a cornerstone in various industrial applications due to its ability to withstand extreme conditions. However, when it comes to flexibility, tungsten has been underestimated.

The Challenge: Flexibility

The misconception about tungsten's flexibility arises from its natural rigidity. People often assume that a material so robust must lack the pliability needed for certain applications. Breaking free from this conventional view, tungsten wire has been engineered to offer a surprising degree of flexibility, making it a versatile option for diverse industries.

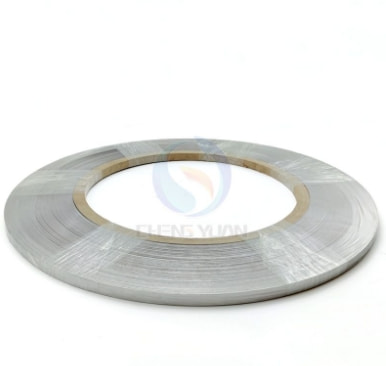

Tungsten Wire Manufacturing Process

To understand the newfound flexibility of tungsten wire, it's crucial to explore its manufacturing process. Tungsten wire is meticulously crafted through a series of intricate steps. Alloys are introduced during the manufacturing process to enhance the wire's flexibility without compromising its inherent strength. This delicate balance ensures that tungsten wire can now bend and adapt to various shapes without losing its structural integrity.

Applications in Real Life

Now, let's bring tungsten's flexibility into the real world. This exceptional wire finds its way into numerous industries, contributing to innovations that touch our daily lives. In the aerospace sector, where materials must withstand extreme conditions, flexible tungsten wire plays a pivotal role in creating resilient components. Additionally, the automotive industry benefits from tungsten's flexibility in manufacturing intricate parts, ensuring both strength and adaptability.

Additional reading:What Are Wear Plates Used For?

The Advantages of Hot Rolled Steel Plates

13 FAQ About MPP Power Pipe

What Is A Graphite Electrode?

Sintered Porous Metal Stainless Steel Discs: Versatile and Reliable

Silica Fume Supplier Guide: How to Choose the Right Partner for Your Project

The Benefits of Using Graphite Crucibles

Flexibility vs. Durability

The beauty of tungsten wire lies in its ability to strike a balance between flexibility and durability. Unlike materials that may succumb to stress when bent or shaped, tungsten wire remains steadfast. This duality is particularly advantageous in applications where both traits are essential, such as in the creation of medical devices and equipment.

Innovations in Tungsten Alloy Technology

Advancements in tungsten alloy technology have further propelled its flexibility into new heights. Researchers and engineers continually explore ways to refine the composition of tungsten alloys, opening doors to applications that were once deemed challenging. These innovations ripple across industries, offering solutions that were previously thought to be beyond the reach of tungsten.

Tungsten in Electronics

In the realm of electronics, where precision is paramount, the flexibility of tungsten wire takes center stage. It is employed in the manufacturing of various electronic components, contributing to the reliability and functionality of devices we use every day. The ability of tungsten wire to bend without breaking enhances the durability of these components, ensuring a longer lifespan.

Medical Applications

In the medical field, flexibility is not just a desirable trait but a necessity. Tungsten wire finds itself in the construction of medical equipment, where its flexibility ensures optimal performance. From intricate surgical instruments to medical imaging devices, tungsten plays a crucial role in shaping the future of healthcare.

In conclusion, the question of how flexible tungsten wire is no longer carries the assumption of rigidity. Thanks to innovative manufacturing processes and advancements in alloy technology, tungsten wire has emerged as a flexible and reliable material. Its applications in aerospace, automotive, electronics, and healthcare showcase the versatility of this once-misunderstood substance. So, the next time you encounter tungsten wire, appreciate its strength, but also acknowledge its newfound flexibility.

Why is the price of tungsten rising?

Which industry produces silica fume?

What is a pure metal?

Guidance for Airport Perimeter Security

The Application and the Function of the Glass Beads

Best Horse and Livestock Fence Panels For Your Cattle Ranch

What is the difference between security screen and security film?